We are capable of providing, subject to the strictest respect for your quality criteria, all or part of the services you require in the following specialities.

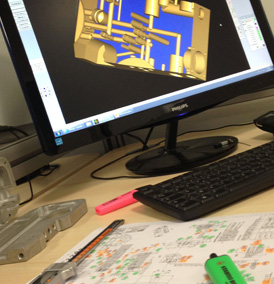

Our mechanical research office comprises a series of Pro-Engineer, Solidworks and Catia V5 workstations.

We can provide broad engineering support, from mere changes to form to research into complex mechanical units, including technical and economic optimisation, the choice of materials,…

Our production, with integrated laser cutting using a recent and high performance machine, offers the highest levels of productivity and competitiveness.

From thin layers up to 20 mm, in steel, aluminium and stainless steel, TMI is positioned as a specialist in laser cutting for semi finished integrated products or via sub contracting.

Arc welding and inert gas welding, robotic welding or spot welding, our industrial equipment and recognised know-how enable the production of the most complex pieces of metalwork, strictly respecting your technical specifications.

TANCOGNE provides you with a system optimised for the production of simple to complex parts.

With capacity of over 10,000 hours a month, our machinery pool comprises 2 and 3 axle cycle lathes, 3, 4 and 4 axle digital machining centres, vertical, horizontal, palletized…

Internally or via our network of sub contractors we provide liquid and powder paint, polishing, microblasting, as well as all the surface and thermal treatments necessary.

Our teams carry out assembly operations, from the simplest sub-unit to the most comprehensive products and contracts.

We also integrated the complete management of the purchase of components used in our manufacturing process.